How to Create Safety Training Programs in the Workplace

Safety professionals understand how critical training programs are to keeping workers safe. Unfortunately, accidents happen every day. In 2023, the United States Bureau of Labor Statistics received reports of 5,283 fatalities. In 2024, businesses reported 5,292 severe injuries and 4,271 hospitalizations to the Occupational Safety and Health Administration (OSHA). The most common event was falling on the same level. Proper training on safety procedures can help reduce the number of incidents and injuries. This guide shows you how to create a safety training program in the workplace in six steps.

The Importance of Safety Training

Safety training programs in the workplace are essential for helping prevent injuries, illnesses, and deaths. In many industries, regulations require training. It improves a worker’s ability to identify hazards, as well as their productivity and morale. In addition to equipping professionals with the knowledge to prevent injuries and accidents, safety training helps reduce disruptions, workers’ compensation claims, and insurance costs.

Traditional approaches to safety were often reactive, only taking action after someone became sick or hurt. Modern safety training is more effective and proactive, helping businesses find and mitigate hazards before they cause problems.

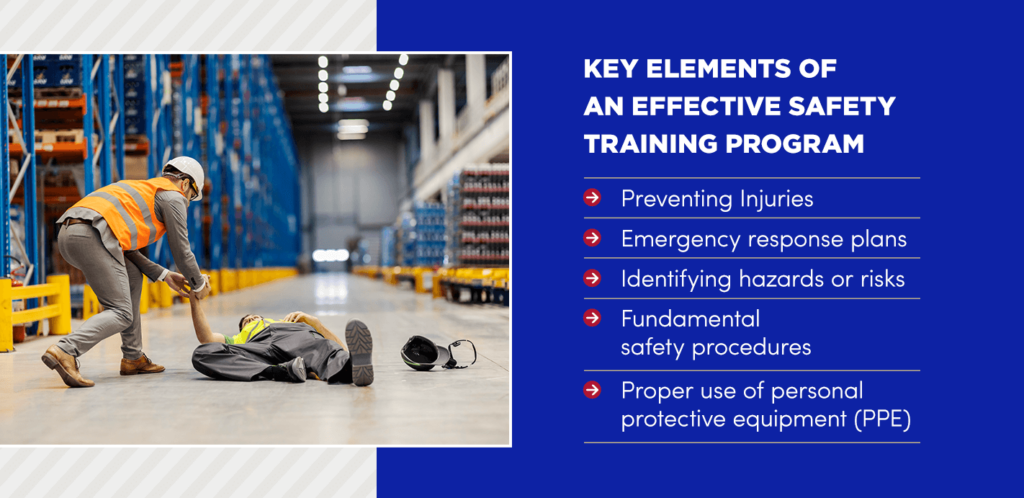

Key Elements of an Effective Safety Training Program

The features of your specific safety program may vary depending on your industry and business needs. However, most training programs include most of the following elements:

- Preventing injuries

- Emergency response plans

- Identifying hazards or risks

- Fundamental safety procedures

- Proper use of personal protective equipment (PPE)

If you don’t already have a program in place, begin with a basic program that addresses the most severe or frequent risks and expand from there. OSHA’s recommended practices for health and safety programs and the training requirements in their standards are good places to start. Keep in mind that state safety plans may have additional training requirements that go above and beyond federal standards. Publication 2254 is also a good place to start since it provides the training requirements for general industry and construction standards.

6 Steps for Creating a Safety Training Program

Whether your training needs are simple or complex, building a program generally follows the same steps. Here’s how to create a safety training program.

1. Identify Your Training Needs

The first step is to understand your training needs. If you have a current training program, evaluate its effectiveness. You can also use worker surveys to learn how team members view the current program. Performing job hazard assessments (JHAs) can help establish worker buy-in and involvement in creating safety training programs.

Consider if the same training will work company-wide or if you’ll need job-specific training. You may also need training for contractors working in your facility. Reviewing past accident or incident reports can help you identify existing safety issues so you know what to address. You may also need to include certain training types to comply with regulations or industry requirements.

2. Define the Learning Objectives

It’s easier to evaluate the success of your program if you establish clear objectives for what workers should know and be able to do after the training. Organizing goals to be specific, measurable, achievable, relevant, and time-bound (SMART) can prevent overly broad or vague objectives. For example, you might try to decrease injuries by 10% year-over-year. To achieve that goal, you might focus on having workers:

- Identify three common hazards.

- Demonstrate proper use of PPE.

- Understand how to report unsafe conditions.

Depending on your situation, your goals might include ensuring employees know how to protect themselves and their co-workers, respond to emergencies, or make suggestions for improvements.

3. Develop the Training Content

Create a well-defined, written plan for your training program. Include the scope, goals, objectives, delivery methods, and frequency. You might have multiple plans depending on why the training is taking place. For example, training during onboarding will differ from training on a new piece of equipment. Other times that may necessitate training include if workers change roles, if you implement a new process, if new risks and hazards are discovered, or if the situation requires it. For example, an increase in powered industrial truck incidents indicates the need for refresher training. In certain industries, regulations may require employees to refresh their training regularly to comply with continuing education regulations.

Keep in mind that you may need to create training documents in multiple languages to ensure accessibility for all employees.

4. Select Your Training Methods

Choosing the right approach to deliver your training can seem complicated since there are so many options. Luckily, you don’t need to pick just one. Using a mix of training methods can improve knowledge retention. Adults generally learn best when they are actively engaged and can interact with others. Aim for no more than one-third of your training time to be lecture-based and the remaining two-thirds to be activity-based. You might also use these other methods:

- Discussion

- Simulations

- Case studies

- Quizzes or polls

- Demonstrations

- Interactive games

- Hands-on activities

- Multimedia, such as images, infographics, videos, and animations

Many training programs are available on-site, in a classroom, or online. With on-site training sessions, employees don’t need to travel, and you can easily customize sessions for your specific workplace. On-site and classroom training sessions allow workers to collaborate and ask questions, which can help them understand the material thoroughly. Classroom sessions often place more emphasis on training the trainer, so employees can return to the workplace and teach others.

With online training sessions, workers can learn at their own pace, making it more efficient. Online sessions can provide improved accountability and make it easier to offer learning accommodations, such as multiple languages.

You may also see behavior-based safety (BBS), human and organizational performance (HOP), and psychological health and safety (PHS) methods. While some people think you must choose one or the other, these methods aren’t incompatible. HOP generally focuses on processes and systems; BBS focuses on personal behavior, guidance, and feedback; and PHS focuses on emotional and psychological factors that affect an individual’s susceptibility to unsafe situations. These methods work well together for a more holistic program.

Whichever methods you choose, you should emphasize the reasons behind the rules. Workers should understand why they should take certain actions and the consequences of unsafe behavior. Consider sharing past accidents or near misses from your own workplace and statistics on workplace safety more broadly. You might also explain any legal requirements and the implications of noncompliance.

5. Implement the Training Program

Schedule and deliver the training, ensuring active participation and engagement. Breaking training into multiple sessions can prevent information overload, improve retention, and minimize operational disruptions. If everyone needs to go through a new training, consider staggered sessions or flexible online options that can be done at any time. Be sure to have all the necessary materials and equipment ready if you’re administering training on-site.

You’ll want to keep accurate records of training attendance and completion, especially if you must verify training to comply with regulations.

6. Evaluate the Program’s Effectiveness

After the training is complete, evaluate its effectiveness by comparing pre- and post-training assessments. You’ll also want to track key metrics, such as injury rates, to determine whether you met your objectives. Monitor on-the-job performance, and aim to analyze incidents or near-misses to see if training could be the cause or could offer a solution.

Safety training should be an ongoing process. Continually evaluate and revise your program to improve processes and ensure relevancy as the company’s needs change. You can seek employee input using training exit surveys, periodic assessments, or feedback requests to better understand their perspectives. This process helps ensure your program remains effective and contributes to a safer workplace.

Learn How to Implement Safety Training Programs With NASP

Get the skills you need to implement and manage safety training programs with courses from the National Association of Safety Professionals (NASP). Our Certified Safety Manager course allows you to train employees on policies and procedures. There are no prerequisites, though a basic understanding of environment, health, and safety (EHS) in the workplace can be helpful. The classroom course is a 40-hour course that takes place over one week. The online course should also take about 40 hours, but you can do it at your own pace — you have up to six months to complete the class. Register today to start building your workplace safety training program!

Related Posts