Debunking a Common Myth: Can OSHA Cite You for Not Having an Arc Flash Label?

As a safety professional, you’ve likely heard it in meetings or on the shop floor: “If OSHA sees that panel without an arc flash label, we’re getting a fine!” It’s a common belief that the Occupational Safety and Health Administration (OSHA) directly enforces the National Fire Protection Association’s (NFPA) 70E standard, specifically the requirement for arc flash warning labels on electrical equipment.

While born from a genuine concern for safety, this statement is technically a misconception. This seemingly small distinction in regulatory authority can lead to a dangerous sense of complacency or, conversely, confusion about what is truly required. Let’s clear up the confusion and understand how OSHA actually approaches electrical safety and the critical role NFPA 70E plays in enforcement.

The Core of the Misconception: OSHA vs. NFPA 70E

First, it is crucial to understand the distinction between the two organizations. OSHA is a government regulatory agency that creates and enforces laws (standards) that have been passed through a formal public rulemaking process to ensure worker safety. NFPA, on the other hand, is a non-profit, standards-developing organization that creates and publishes voluntary consensus standards and codes, which are developed by committees of industry experts.

OSHA does not incorporate the entirety of NFPA 70E, Standard for Electrical Safety in the Workplace, into its regulations. Therefore, an OSHA compliance officer cannot simply walk into your facility, point to a missing label on a panel, and write a citation for “Violation of NFPA 70E, Article 130.5(H).”

So, does that mean you can ignore the labeling requirements? Absolutely not. While OSHA won’t cite the NFPA 70E article directly, they have several powerful and well-established tools to cite the underlying hazards that arc flash labels are designed to address. Ignoring the principles of NFPA 70E leaves an employer exposed to significant liability.

How OSHA Cites Arc Flash Hazards Without Citing NFPA 70E

OSHA’s standards are often performance-based, meaning they mandate a safe outcome without always prescribing the exact method to achieve it. This is where NFPA 70E becomes critical. OSHA views NFPA 70E as the industry-recognized consensus standard—the “how-to” guide for meeting its broader electrical safety requirements.

Here are specific OSHA standards an inspector can, and will, use to cite an employer for failing to protect workers from arc flash hazards:

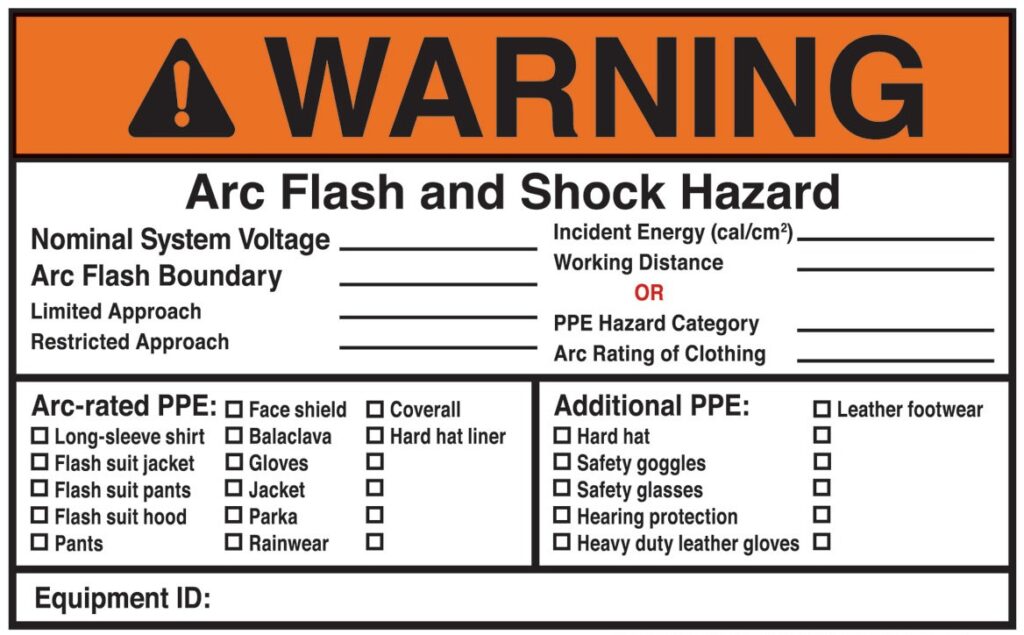

- 29 CFR 1910.132(d)(1) – Personal Protective Equipment (PPE) Hazard Assessment: This standard requires employers to assess the workplace to determine if hazards are present that necessitate the use of PPE. An effective assessment for electrical hazards goes beyond simply identifying voltage; it requires quantifying the potential thermal energy of an arc flash through an incident energy analysis. The arc flash label is the direct output of this analysis, communicating the specific hazard level and required PPE. A missing label is therefore clear evidence that a proper hazard assessment has not been performed or its results have not been communicated to employees.

- 29 CFR 1910.269(l)(8)(ii) – Electric Power Generation, Transmission, and Distribution: This is a more specific standard for the utility industry that contains a direct requirement for assessing incident energy. It sets a clear precedent that OSHA considers the calculation of potential arc flash energy to be a required step in protecting workers.

- The General Duty Clause – Section 5(a)(1): This is OSHA’s ultimate catch-all. It requires a workplace “free from recognized hazards.” To issue a General Duty Clause citation, OSHA must prove a hazard existed, it was recognized by the employer or industry, it was likely wto cause serious harm, and a feasible means of abatement existed. In an arc flash case, NFPA 70E single-handedly provides the evidence for recognition and feasibility. The standard proves the hazard is recognized by the entire electrical safety industry and lays out the feasible steps—hazard analysis, labeling, training, and PPE—to correct it.

Evolving Guidance and Real-World Enforcement

OSHA’s stance has been clarified through various letters of interpretation and demonstrated in actual citations.

A Telling Letter of Interpretation

A key piece of guidance is a November 2006 Letter of Interpretation where OSHA clarified its position. Interestingly, this letter originally included a footnote that directly referenced the NFPA 70E-2004 requirement for field-marking equipment with an arc flash warning. This footnote was later removed, underscoring OSHA’s deliberate legal effort to avoid the appearance of directly enforcing a specific consensus standard. However, the core message remains unchanged and is frequently reinforced: NFPA 70E is the benchmark for a compliant and defensible electrical safety program.

Real-World Example 1: Fatality Leads to Willful Violations

Following a 2022 worker fatality caused by an arc flash and blast, OSHA issued citations for willful and serious violations totaling over $330,000. The investigation found multiple failures in the company’s electrical safety practices. A key finding in the citation stated: “For each employee exposed to hazards from electric arcs, the employer did not make a reasonable estimate of the incident heat energy to which the employee could be exposed.”

This “reasonable estimate” is the core of an arc flash program, and NFPA 70E provides two distinct methods to achieve it. The failure to use either method is what constitutes the violation.

- The PPE Category Method (The “Tables”): This method allows a qualified worker to use detailed tables within NFPA 70E to determine the required Arc Flash PPE Category for a specific task. While fairly cost-effective upfront, this method places a significant analytical burden on the worker in the field. To use the tables correctly, the worker must verify complex parameters on-site, such as the maximum available fault current and the clearing time of the upstream protective device, which is often difficult and time-consuming. If the parameters fall outside the table’s limits, this method cannot be used.

- The Incident Energy Analysis Method (The “Arc Flash Study”): This is a much more robust method that involves a detailed engineering analysis of the power system, typically performed by engineers using specialized software. This study calculates the precise incident energy (in cal/cm²) available at each piece of equipment. The benefit is that it removes the guesswork and complex decision-making from the field employee. The results are printed on a label, allowing the worker to simply match their PPE rating to the number on the sticker. While this method requires a greater initial investment, it provides a much more accurate and user-friendly result.

When an employer fails to perform this “reasonable estimate,” they have not completed the necessary due diligence required by either of these industry-accepted methods, leaving workers dangerously exposed.

Real-World Example 2: General Duty Clause for Arc Flash Burns

In a separate 2020 incident, a maintenance employee suffered third-degree burns from an arc flash while operating a 480V knife switch. OSHA investigated and cited the employer under the General Duty Clause, with an initial proposed penalty of $13,494. The citation focused not on the lack of a label itself, but on the employer’s failure to furnish a workplace free from a recognized hazard—in this case, the hazard of an arc flash event for which the employee was not adequately protected or informed.

The Final Word

Don’t get caught up in the semantics of which standard is being cited. Whether it’s the General Duty Clause or a specific electrical standard, OSHA relies heavily on NFPA 70E to define what a safe electrical work environment looks like and what constitutes a feasible means of abatement.

The arc flash label is not just a sticker; it’s the culmination and communication of a critical safety process: the arc flash risk assessment and incident energy analysis. Its absence is a red flag to an OSHA inspector that this vital process has likely been neglected, leaving employees exposed to deadly, life-altering hazards. Instead of asking, “Do we need a label to avoid a fine?” the more vital question for every safety professional is, “Have we done the analysis to understand our hazards and properly protect our people?” When you can answer “yes” to the second question, the label becomes the logical and necessary final step.

Related Posts