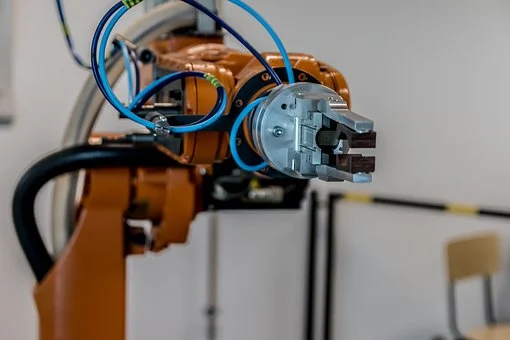

Workplace Robotics Cause Safety Concerns

It is of no surprise that robots are beginning to take root in all areas of industry in the United States. Technology advancements in recent years have led to Artificial Intelligence that is able to complete multiple technical tasks at an unprecedented pace. With this increased use in robotics, employers have begun to see an uptick in potential hazards and injuries.

While the use of robots increases safety in certain areas, such as the removal of employees from dangerous environments and locations, without the proper guidelines in place to ensure robotics safety, these injuries could resurface from the robots.

For example, a worker at a water bottling company was killed after attempting to remove a piece of plastic from the forks of a driverless forklift, also known as a laser guided vehicle. The manufacturer’s manual requires workers to initiate an emergency stop before removing an obstacle detected by the LGV, but the worker did not, resulting in the vehicle resuming its task as soon as the plastic was removed.

To prevent injuries and potential fatalities such as this one, NASP suggests the following recommendations:

- Write company safety procedures with the manufacturer safety requirements in mind. Quoting the requirements verbatim in procedure will limit the chance of a potential injury while ensuring employees follow guidelines written specifically by the manufacturer.

- As with any industrial powered truck training, it is imperative to train workers about the specific hazards of each piece of equipment. Employees should have training that is relevant to each individual piece of robotic equipment.

- Ensure compliance through the use of refresher training and spot check. Spot checking can be added into managerial review checklists.

The National Institute for Occupational Safety and Health (NIOSH) said that the relative newness of robots in the workplace has made it difficult to know what regulations need to be made in order to ensure safety. Therefore, the documentation of these accidents is vital to the continuation of robotics safety efforts.

To begin to solve this, NIOSH established the Center for Occupational Robotic Research to increase worker safety while using robots. This center will begin building a research portfolio that includes efforts to document risk to workers through surveillance and fatality investigations.

Related Posts